Driving the Future of Digital Manufacturing

Connected Manufacturing Forum 2024

June 25 - 26, 2024

Westin Buckhead Atlanta, GA

Avoid Rogue Spending

Don't miss out on your opportunity to save $300 Register before April 30th to secure your largest discount offer!

Connecting People, Process & Technology

The goal of the Connected Manufacturing Forum, which we've been running since 2018, is to accelerate the digital transformation and enablement of factories across America to boost efficiency, productivity and profitability. This is THE event where manufacturers of all sizes come together to benchmark, network, and learn how to become a smarter, more connected manufacturer.

Join 200+ leading Manufacturing, Operations, Technology, Supply Chain and Advanced Engineering executives for a collaborative debate on the latest Industry 4.0 (& 5.0!) trends, challenges and opportunities.

Couldn’t Have Said It Better Ourselves

“Great speakers, right topics, correct attendees”

Peter Denmark

Business Director

Ultimaker

“This conference provided valuable opportunities to connect with industry peers and vendors in several ways, including networking events, panel discussions and roundtables."

Eric Wespi

Data Scientist

Boston Scientific

“Sessions were of very high quality!”

Josef Kriegmair

Senior Manager

MTU Aero Engines

Our Speakers, Your 2024 Visionaries

Allen Turner

Innovative Solutions, SME

International Paper

Scott Gregg

Global Digital Plants Director

Mars Wrigley

Paul Ingram

Director Digital Manufacturing

Nestle-Purina

Hans Berghorst

VP Manufacturing Assets & Technology

Dairy Farmers of America

Ricardo Estok

Global Operations Optimization - Transformation

Goodyear

Ashish Rastogi

Senior Director – Supply Chain Strategy, Optimization and Advanced Analytics

Western Digital

Jenny Taylor

Lead, Digital Transformation, Innovation - XR/VR

Duke Energy

Jesper Toubøl

VP Operations – Moulding Production

The LEGO Group

Emma van de Laar

AI & Analytics Lead

Mars Wrigley Europe

Hear From Those Paving the Way in Manufacturing

Day 1 – June 25, 2024

Competitive Imperative: The Crucial Alignment of Business Objectives With Smart Manufacturing Goals

- KEYNOTE

The Tipping Point: How Autonomous and Collaborative Robots Add Value, Increase Productivity, Reduce Waste and Improve Worker Ergonomics - PANEL

The Challenges of Optimizing the Supply Chain With Different Manufacturing Approaches and Technologies Used at the Factory Level - Track A

High-Fliers – for Manufacturers in the More Advanced Stages of Their Industry 4.0 Journey - Track B

Industry 4.0 Take-Off and Acceleration – for Manufacturers in the Early to Intermediate Stages of Their Digital Transformation Journey - CASE STUDY

Agile vs. Waterfall Methodologies to Deliver and Iterate Manufacturing Projects Faster and More Cost Effectively

Day 2 – June 26, 2024

How I4.0 Partnerships, Workforce Collaboration, Upskilling, and Data Analytics

- KEYNOTE

Plant Optimization: Standardizing Factory Operations and Culture to Ease Tech Deployment and Integration to Meet Strategic Business Objectives - PANEL

The Best Use Cases for AI in Advanced Manufacturing - TRACK A

The Digital Backbone: Using and Understanding Data to Improve Production and Business Outcomes - TRACK B

The Connected Worker: Upskilling, and Cross-Functional Training for Full Digital Enablement - Deep-Dive Workshop:

Unifying and Contextualizing Data in the Cloud for Improved Data Visualization and Sharing

For All the Major Players in One Place

You will rub shoulders with Manufacturing, Operations, Technology, Supply Chain and Advanced Engineering executives from Top 500 manufacturing companies, as well as the world’s most innovative start-ups, including:

Growing a Greener Future.

The Connected Manufacturing Forum is dedicated to creating a more sustainable world for this generation and future ones. By registering for the event, will automatically be donated to One Tree Planted on your behalf. Want to get involved?

Learn MoreReal Reviews From Real Attendees

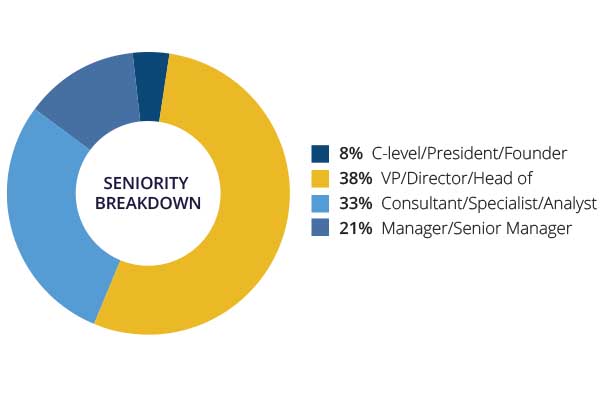

Connected Manufacturing in Numbers

Industry Breakdown

The Connected Manufacturing Difference

Actionable Industry 4.0 Use Cases

We're not a trade show or a vendor-led seminar where the main goal is to sell the solution to you.

Our agenda is 100% focused on your biggest challenges and opportunities. You’ll walk away with pages of actionable strategies to help you become a smarter, more connected manufacturer.

A Program Tailored to Manufacturers of All Sizes

We bring together every facet of manufacturing, from Top 500 manufacturing companies, to the world’s most innovative start-ups.

No matter your industry, whether it be food & beverage, aerospace, automotives, engineering services - or any other, you’ll receive detailed, strategic content focused on all aspects of advancing to the next phase of manufacturing.

Cross-Sector Learning & Networking

Benefit from meeting Industry 4.0 leaders, and tons of peers, with over 10 hours of discussion groups, tracks, roundtables every day.

You’ll develop relationships, make new contacts and speak “off-the-record” with your peers from different sectors and verticals.

How You’ll Network Better

Better networking in small groups

We learn better by doing

Engage experts in multiple ways!

We custom-build interactive sessions so you'll learn more and actually enjoy meeting people.

Plus, rotating formats hold our attention longer - you won't find these at any other event!

Keynote

Panels

Fireside

Chats

Case

Study

Rotating

Roundtables

Couldn’t Have Said It Better Ourselves

“If you want to truly get connected with the best minds in the industry to share ideas and experience, the Connected Manufacturing Forum is the place to do just that.”

Stephen Childs

VP/CHRO, Global Human Resources

Panasonic Automotive

“Very informative and worthwhile for anyone interested in connected manufacturing and the IoT.”

Fernando Garcia

International Trade Economist

United States International Trade Commision

"The panels had experienced individuals from a diverse background and that enabled the attendees to have the complete perspective of the journey and associated best practices and lessons learned.”

Hicham Wazni

Corporate Director of Manufacturing Intelligence and Smart Manufacturing

Howmet Aerospace

Join Our Community

Embrace Innovation in the Heart of the South

Westin Buckhead Atlanta

June 25 - 26, 2024

3391 Peachtree Road, N.E.

Atlanta, GA 30326

(404) 365-0065